A thorough maintenance regime is necessary to prevent component failure, reduce system ‘down-time’ and maintain performance. HSB offer a range of services to assist with these regimes but we are also here to help when a component fails.

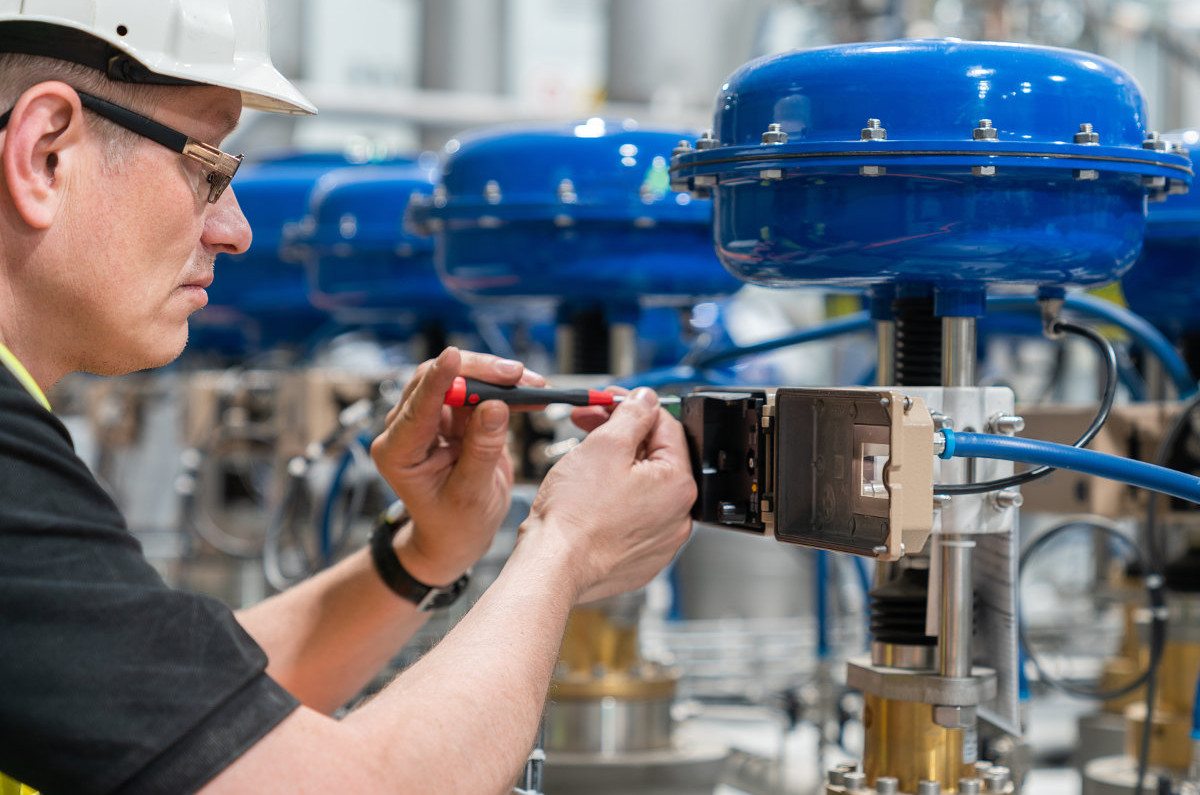

Valve Repair & Reconditioning

HSB has been specialising in the overhaul and maintenance of industrial valves since our inception, our aim is to ensure valves are repaired to the highest standard utilising OEM parts within a quick turnaround. We can provide a full valve overhaul and pressure testing service on the majority of valves, from a wide range of manufacturers. Our customers based in the North West benefit from a friendly personal door-to-door service, with most valves collected next day.

To assist with your Annual Boiler Insurance obligations and critical valve assets, we offer a complete door-to-door service which includes;

- Collection of all associated valves and gauges

- Stripping, inspection, overhaul and testing of valves

- Testing and calibration of gauges

- Return of all components including any necessary boiler spares (door joints, packing sleeves etc.) prior to your final Boiler Inspection

Plate Heat Exchangers

Due to their nature Plate Heat Exchangers (PHEs) require regular maintenance to ensure optimum performance as the internal surfaces are prone to fouling and the channels can become blocked with debris in untreated systems. HSB offer both a plate renewal service as well as replacement plate packs (and fitting) for a wide range of makes and models. Our plate renewal service consists of stripping the PHE and removing the entire plate pack, the plates are then cleaned using high pressure water or ultrasonically depending on the degree of fouling. Once cleaned gaskets are re-fitted to the plates and the pack re-sequenced before being delivered back to site. To reduce down-time we recommend that a spare plate pack is held in stock to allow for scheduled maintenance and cleaning.

Tube Bundles

Tube Bundles are used for a variety of heat transfer applications with a number of different mediums including; Chilled Water, LTHW, DHW and Steam. HSB offer a complete Tube Bundle Repair & Inspection service for all types of heater which includes;

- Initial Inspection and Pressure/NDT Testing

- Written Condition Report c/w Recommendations

Depending on our findings;

- Cleaning

- Re-building of baffles/welds

- Re-tubing

- Replacement

Our service also includes inspection, testing and refurbishment/replacement of the primary header chest if required. All tube bundles which are removed and inspected by ourselves are re-delivered with replacement gaskets as necessary.

All works are completed to the relevant standard, with the necessary documentation provided. If required, we are also able to provide calculations relating to heat transfer, strength etc.

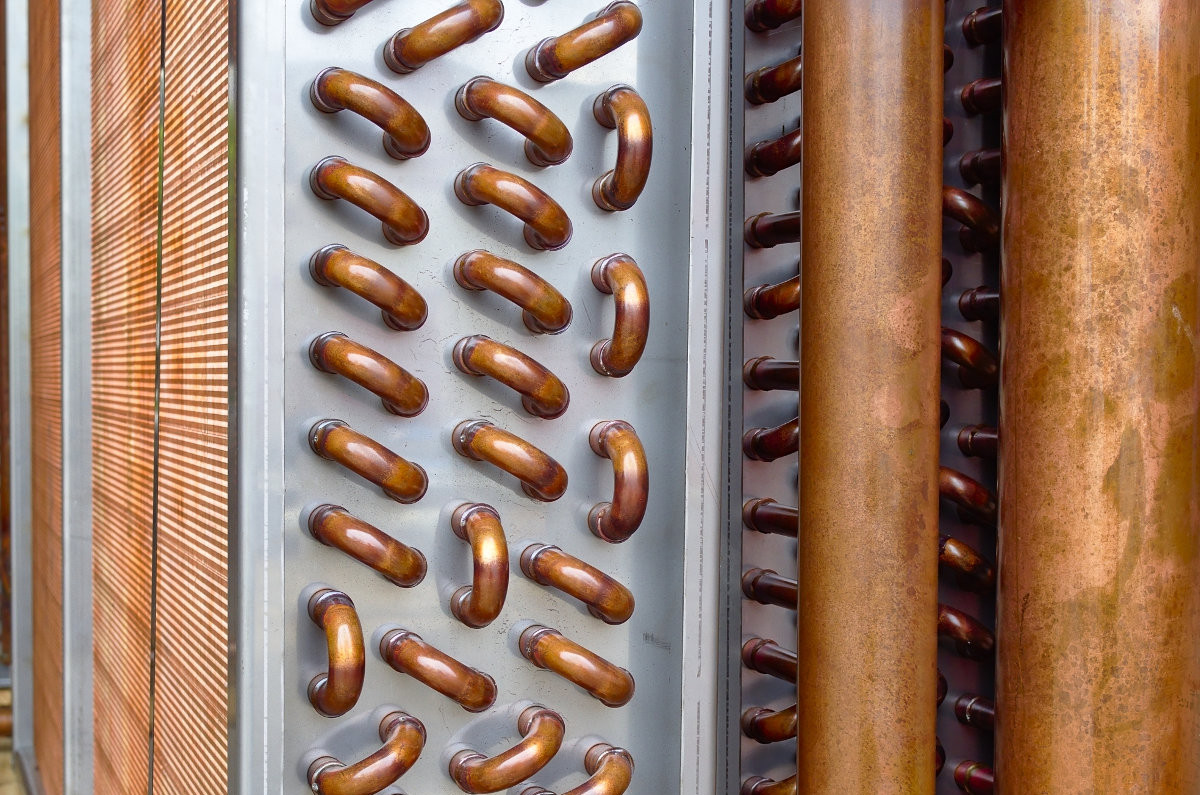

Coils

Coils for Heating, Cooling and Heat Recovery can be tested and repaired, or in the event of component failure, a like-for-like replacement can be made to order. Dependent on size, we will arrange a site visit to measure the existing unit or collect from site to utilise as a template. All of our coils are manufactured using copper tubes with aluminium or copper fins with a variety of casing material options.

Spool Pieces & Pipework Assemblies

As technologies have progressed and manufacturing processes have improved, pumps and valves have reduced in size therefore in some instances, that replacement pump is just a little bit shorter than its predecessor. As part of our scope of supply we can provide made-to-measure spacers and spool pieces (including gaskets and bolts if necessary) to ensure that your new piece of equipment slots straight in. This is particularly useful in critical applications as we can significantly reduce down-time by specifying standard off-the-shelf products which are available quickly rather than waiting on those long lead-time items.

Using our expertise in pipework design and fabrication we are also able to offer bespoke pipework assemblies manufactured off-site to avoid the requirement for permits and reduce time spent on site. We are able to work with a range of different materials for a variety of applications including hot water, chilled water, condensate and steam. Previous assemblies include; PRV Stations, manifolds and low loss headers.